Related content

-

4 Ways Ceramic 3D Printing Technologies Are Paving the Way for the Future

Ceramic 3D printing has always been a popular application of additive manufacturing, yet still on the relative margins when compared to thermoplastics or metals. Naturally, metals and plastics are quite prominent in our daily lives, so it’s no wonder they take up more of the additive manufacturing world as well. Ceramics, while a large part of much of our day-to-day appliances, are less often additively manufactured. Still, ceramic 3D printing technologies are increasing in popularity and can be quite impressive, as recent research projects have proven.

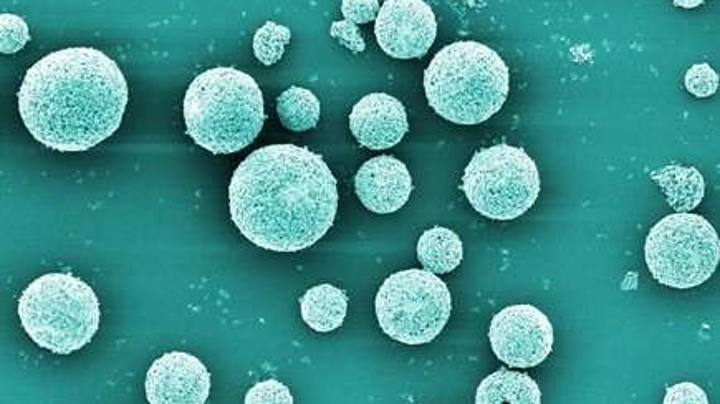

Ceramic granules made of aluminum oxide were coated with a nanometer-thin layer of copper oxide, as shown here at 5,000-fold magnification (electron microscopy, colored).

Removing pathogens from drinking water is especially difficult when the germs are too tiny to be caught by conventional filters. Researchers at Empa and Eawag are developing new materials and processes to free water from pathogenic microorganisms such as viruses.

Water is life, biology teaches us. Reality teaches us something different: Water contaminated with pathogens causes hundreds of thousands of deaths each year in places where water treatment is lacking or poorly functioning. To put an end to this, the availability of clean water for all mankind has been included in the United Nations (UN) Global Sustainability Agenda since 2015. In accordance with this goal, Empa researchers, in collaboration with their colleagues at Eawag, are developing new materials and technologies to remove pathogens from drinking water, which until now could hardly be eliminated with conventional measures, or only with expensive and complex processes.

Tiny pathogens

The researchers are aiming at the smallest of germs: Tiny pathogens that—unlike the currently circulating coronavirus SARS-Cov-2—are spreading via contaminated water and thus cause various water-borne diseases such as polio, diarrhea and hepatitis. Among these pathogens is the rotavirus, which is only about 70 nanometers in size.

"Conventional water filters are ineffective against rotaviruses," explains Empa researcher Thomas Graule from Empa's High Performance Ceramics lab in Dübendorf. However, it is precisely these tiny germs that are among the most common pathogens causing gastrointestinal infections. According to the World Health Organization (WHO), in 2016 around 130,000 children worldwide died from rotavirus infections. The researchers have now developed strategies for filtration technologies based on new materials that cleverly circumvent the problem of minuteness. This is because one property of the virus particles can be used for a new type of filter: the negative electrical charge of the virus particles.

Based on this idea, the researchers began to develop suitable materials that allow the adsorption of negatively charged virus surfaces. Until now, it has been difficult to create easily regenerated positively charged surfaces with high adsorption capacity, and systematic experimental studies have been scarce. For their investigations, the researchers therefore chose a model virus that is even smaller than the rotavirus: the bacteriophage MS2, which is only 27 nanometers in size—a virus that attacks bacteria but is harmless to humans. Using this model virus, the scientists were able to show that viruses in water adsorb to the filter surface to varying degrees depending on the water's pH. "This must be taken into account when developing new water treatment and filter technologies," says Graule.

Porous nanocoating

In order to develop filter technologies that can capture viruses at the nanometer scale, Graule is focusing on composite materials that are functionalized in such a way that they specifically bind viruses. "In water, the surface of the virus particles is negatively charged. We were able to show how the virus particles attach themselves to positively charged surfaces," he explains. For example, the researcher is working in an international team on ceramic granules made of aluminum oxide, whose fine granules are coated with nanometer-thin layers of copper oxide. "Together with the ceramic, the highly porous copper layer forms a composite material with a positively charged and immensely large specific surface," says Graule. The researchers were also able to coat tiny multi-layer carbon nanotubes with copper oxide, thus enabling virus elimination.

In order to develop a cost-effective and sustainable filter technology, the researchers specifically utilize materials that can be recovered after use in the sense of a closed material cycle. It is also important that no filter components are washed out into the purified water. To this end, analytical methods for nano-safety still need to be developed so that the most suitable composite material can be determined. At the end of the project, a filter technology is expected to be available that is also suitable for water treatment in developing countries with their particularly high numbers of rotavirus and other water-borne diseases.

Worldwide, around 3.4 million people, mostly children in structurally underdeveloped countries, die every year from water-borne diseases. Among the pathogens are single-cell parasites, such as amoebae and lamblia with a size of up to 40 micrometers. Bacteria such as salmonella, which cause typhoid fever, E. coli germs and cholera pathogens are significantly smaller (0.5 to 6 micrometers), but equally potent pathogens. With a size of 25 to 80 nanometers—about 100 to 1000 times smaller—viruses are the most difficult pathogens to filter out of water. In developing countries the contamination of drinking water with rotaviruses is particularly widespread, followed by other viruses such as the pathogens that cause hepatitis and polio.

SOURCE: by Andrea Six, Swiss Federal Laboratories for Materials Science and Technology

沪公网安备31011802004982

沪公网安备31011802004982